Authors:

Bill Gregory, Wayne Evans, Mark Pickles

Abstract:

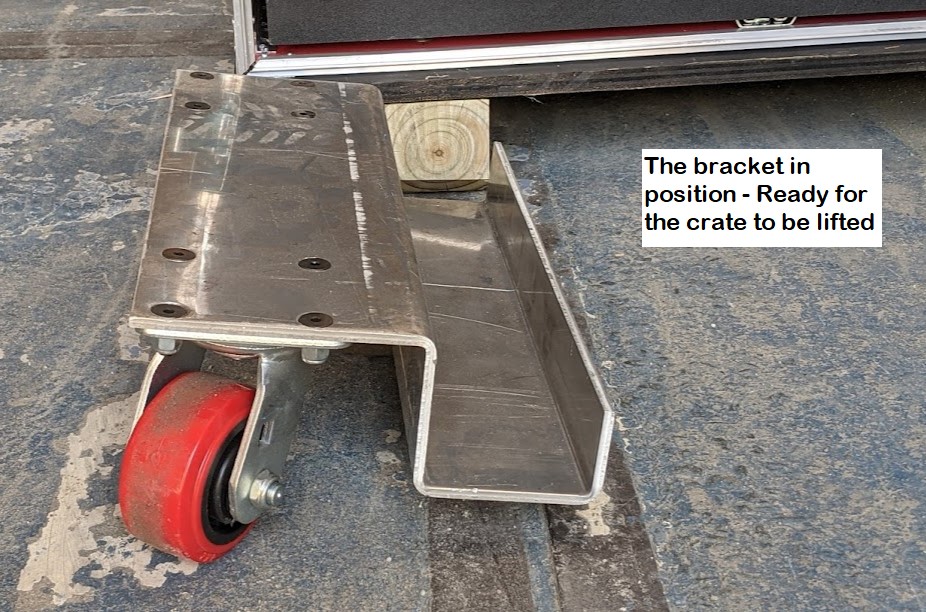

This disclosure proposes a custom metal frame to be created that has heavy-duty casters attached to it. This frame will anchor onto the bottom of the Show Crate without requiring any tools, and without fasteners. The "Z-style" form will wrap around the wooden pallet guide to prevent it from slipping off of the crate, yet the crate's weight is borne by the baseplate of the crate, not the pallet guide.

Background:

Trade show shipping crates are built to protect sensitive equipment during travel and loading onto the convention hall floor. Crates that travel internationally must be stable for air freight - ie., no casters. This causes problems for the equipment owners when the crates are being loaded or unloaded in the home office because it takes pallet-moving equipment to move the crates.

This custom-designed metal bracket with heavy-duty casters enables one person to move heavy trade-show crates in the home office or in a hotel show where pallet-lifting machinery is not available. Trade Show crates are designed to protect equipment while being transported to and from convention sites. International shows require NO Casters because the crates must not roll when shipped by air freight.

Description:

This custom "Z-shaped" bracket fits over the pallet guide on the Show crate. This is a loose fit with the purpose of anchoring the frame so that it does not detach or slide out from under the crate. The full weight of the show crate is borne on the flat surface with the casters.

The fact that it can be installed without any tools or bolts means that the user can install the apparatus. The only requirement is that a pallet lifting device is needed for the installation and removal. This equipment is typically available at any receiving or loading dock.

Claims:

The design point was to create a portable, removable (without tools) and strong conveyance system capable of supporting and moving 1200-2000 pound crates, that did not require our professional white-collar staff to invert the crates or use tools to tighten bolts underneath a crate that was supported by a pallet jack or forklift.

The "Z"-form of the metal bracket uses existing 4x4” standard pallet guides that are on ATA trunks as a means of capturing and securing the caster plate. The weight of the pallet or crate is borne on the flat base of the casters that is outbound of the pallet guides. With this form factor, the casters could alternately be inboard of the pallet guides if the case dimensions require that orientation.

This design is a) portable b) quick and easy to install with one person and one pallet lifter, c) No hand tools are required, and d) it is securely mounted under the crate.

Summary of our claims:

1) Secure mounting of removable crate casters

2) Method of transporting equipment cases within a venue without compromising stability during truck or air shipment.

TGCS Reference 2491