Authors:

Hye Suk Makley

Abstract:

This solution provides a “PEM” style nut design that can be used with thin sheet metal either as an original installation or as a field install for field failures of other existing “PEM” nuts.

Background:

Mem/Press fit nuts are widely used in sheet metal cabinets/designs for screw attachment points. But when dealing with thinner sheet metal housing, you either don't have enough material to have proper 'gripping' material to assemble the PEM nuts or welding them onto the sheet metal can fail in the field.

Description:

Material costs these days are always going up, there is always an effort to cost reduce, which leads to using thinner gauge sheet metal for various cabinets or housing assemblies. This however leads to lack of material to be used to either create a threaded hole or attach a PEM nut to allow usage of screws or other posts that require threaded area for assembly. This lack of material leads to poor assembly of the PEM nuts, where not enough material is there to keep the PEM nut in place, or welding process may fail in field when in use where the PEM nuts pop off, leaving just a hole with no thread area for use.

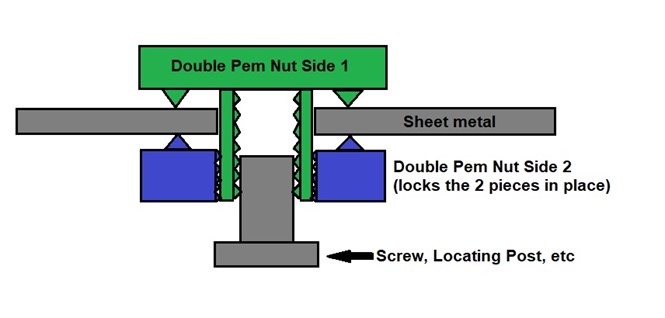

This design solves that issue. The double-sided PEM nut design can be easily attached to thinner sheet metal cabinets or housings, by usage of teeth to keep them in place without wanting to rotate when screw/posts are attached/fastened to them. And the double side allows no additional process to attach the PEM nuts to the housing/cabinet, but just simple use of screw/post to keep them in place without coming off. See attached picture for reference.

This design can also be used as easy field fix/replacement for old PEM nuts that may have failed or fallen off from housing/cabinet unit, which makes it difficult to replace as whole housing/cabinet unit may need to be replaced.

The application can be used in any situations where PEM nuts are used on thin sheet metal parts in the field that fail. Since standard PEM nuts are not easily replaceable, if at all, this idea addresses that issue.

Supporting Art:

Here is an existing nut that has a better grip when using thin sheet metal and has more

overlap to prevent push-out, compared to a PEM clinch nut:

Rivet nut or RIVNUT®

Bollhoff RIVNUT® Knurled Round | Bollhoff Half-Hex Body Rivet Nut (rivetnutusa.com)

How To Install a RIV NUT (youtube.com)

https://www.pemnet.com/products/product-finder/aeks8-580-3-3/

Rivnuts can be install from one side with a special tool or installed by using common

parts…see TGCS FRU 44V2613 nut repair kit for details.

TGCS Reference 4569